In the past few years, Hydrogen (H2) has become one of the most researched gases as an energy carrier because of its variety of applications and environmental friendliness. For the production of Hydrogen, the most commonly used process is Steam Methane Reforming (SMR). Around 95% of hydrogen is produced by this process in the United States. Steam methane reformer lets the user obtain high purity gas in a cost-effective way. Hydrogen generated from steam methane reformer is utilized predominantly in industrial processes for the production of commodities such as ammonia and for petroleum refining because of its high purity.

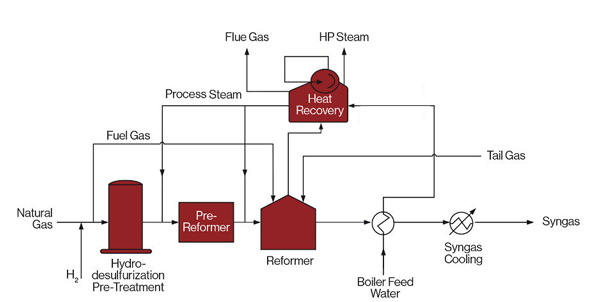

Steam methane reforming is a well-established way to produce Hydrogen. Hydrocarbon and steam enter as a feedstock in the reactor as a result of which carbon dioxide and hydrogen are produced at the end of the entire process.

- CH4 + H2O – CO + 3H2

- CO + H20 – CO2 + H2

- CH4 + 2H2O – CO2 + 4H2

The use of steam methane reformers eliminates the problems associated with storage and distribution of hydrogen cylinders. As compared with all other methods available for the production of hydrogen gas, steam methane reforming is the widely used and most efficient way to generate the gas. Use of hydrogen lowers the carbon dioxide release for fuel cell vehicles powered by natural gas when comparing to those powered by gasoline. SMR also improves the efficiency and reduces production cost, in keeping the price affordable in times of natural gas price fluctuations.

Also Read

MVS Engineering has the ideal answers for all your modern industrial process. It produces the best steam methane reformers that suit all business prerequisites. On the off chance that you have some exceptional prerequisites, we are available to acknowledge them as another open door for us and make a creation framework according to your necessities.