Did you know – Hydrogen is used extensively in Power Plants?

If you guessed that it’s used for producing electricity, then sorry – it’s not.

However, it is used during the process of electricity generation. Hydrogen is an effective cooling agent in electric generators. Power plants must maintain optimal gas purity and pressure inside the generator casings to ensure generation efficiency, operational safety and equipment reliability.

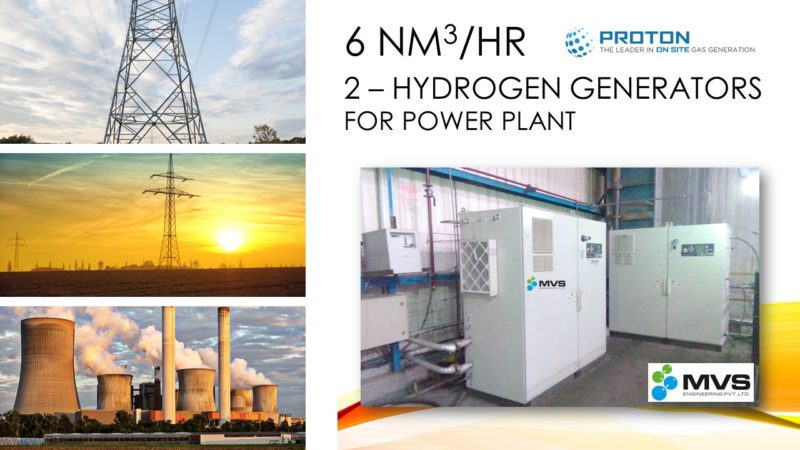

MVS Engineering Pvt. Ltd. has supplied several on-site Hydrogen generation systems to power plants across India, in partnership with world leaders in hydrogen generation equipment – Proton OnSite. Featuring a fully-automated design, Proton’s complete power solutions employ PEM technology to generate hydrogen that maximizes generator capacity, extends generator lifespan and reduces overall costs at plant sites worldwide.

Power plants that do not have an on-site hydrogen generation system have to source hydrogen from outside merchants in cylinder form. This is not only inefficient but has a higher risk due to the constant handling of cylinders. Every time a cylinder is connected and disconnected from the manifold, the risk of hydrogen leakage becomes pronounced.

Our customer in northern India installed 1-Hydrogen plant of Proton OnSite, supplied by MVS Engineering. On MVS recommendation and assurance, the Hydrogen plant was installed within the TG building itself. This is in-fact a safe practice that becomes possible with Proton Hydrogen generators as there is minimal inventory of Hydrogen on-board the system and no storage of Hydrogen otherwise. Hydrogen production from the Proton OnSite generator takes place on-demand.

Once the customer connected the Hydrogen generator to their common Hydrogen header line supplying Hydrogen to the 4 turbine generators (TGs), the Hydrogen generator started to produce as-much hydrogen was being demanded by the various TGs. The customer was now also able to monitor their hydrogen production was the complete operation data of the generator was taken to their central control command center. Due to the ability to study hydrogen production trends, in case of any deviation from the norm, thereby highlighting excessive hydrogen consumption by any TG, the customer is now able to react proactively and take corrective actions on any faults in their power generation equipment and machines.

Also Read

Learn more about how simple and reliable on-site production of Hydrogen can be on our website: https://www.mvsengg.com/products/hydrogen/water-electrolysis/